Automotive Industry Quality Inspection

Industries Covered

- Vehicle Assembly Plants

- Component Suppliers (e.g., tires, glass, electronics)

- Aftermarket Parts Production

- Electric Vehicle and Battery Manufacturing

Part Inspection

Surface defects, dimensions, or coating quality.

In-Process Inspection

Monitoring assembly lines for component misalignments.

Operation Missing Inspection

Detecting missing fasteners, welds, or adhesives.

Label Inspection

Verifying VIN numbers, labels, and certifications.

Assembly Inspection

,aspect=fit)

Ensuring fit and alignment of modules and subassemblies.

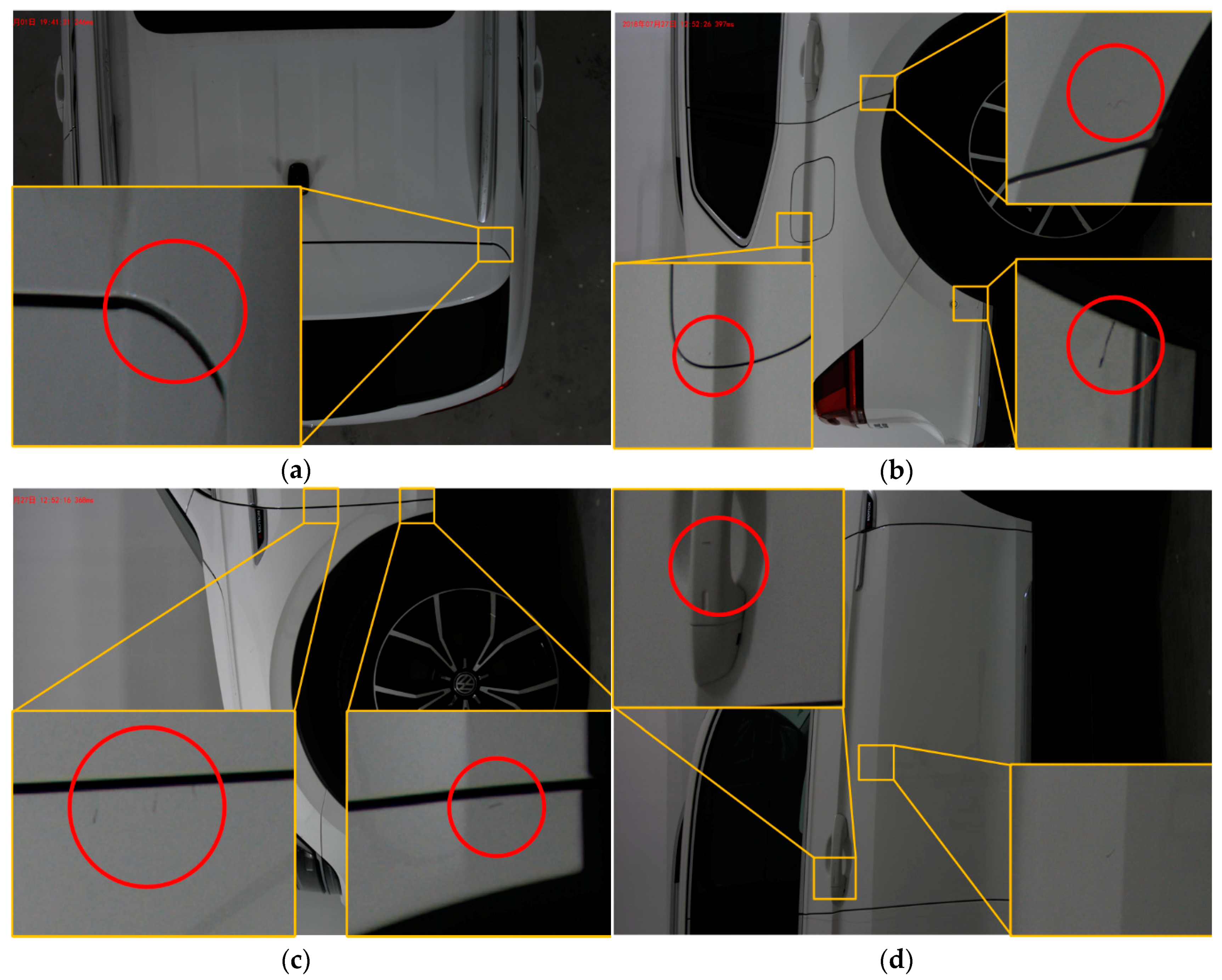

Paint Quality Inspection

Checking for bubbles, scratches, or uneven finishes.

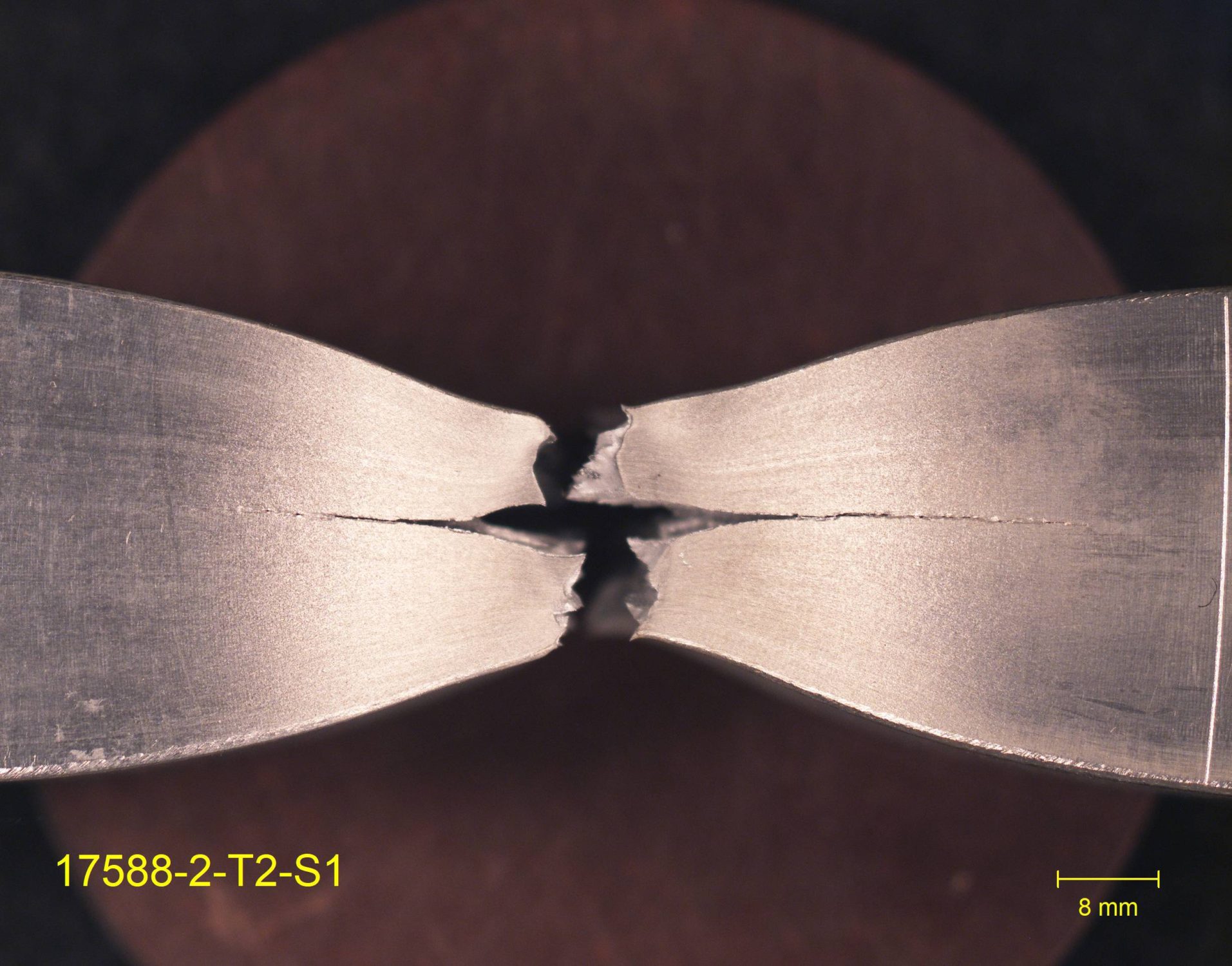

Weld and Bond Inspection

Ensuring structural integrity.

Glass and Light Inspection

Verifying clarity, alignment, and functionality.

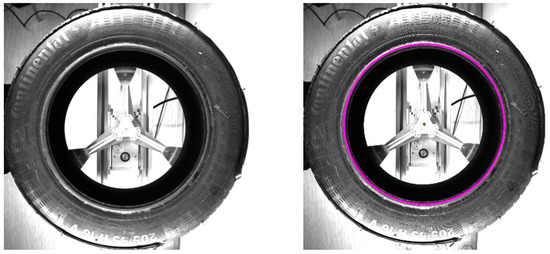

Tire and Wheel Inspection

Ensuring uniformity and absence of surface defects.

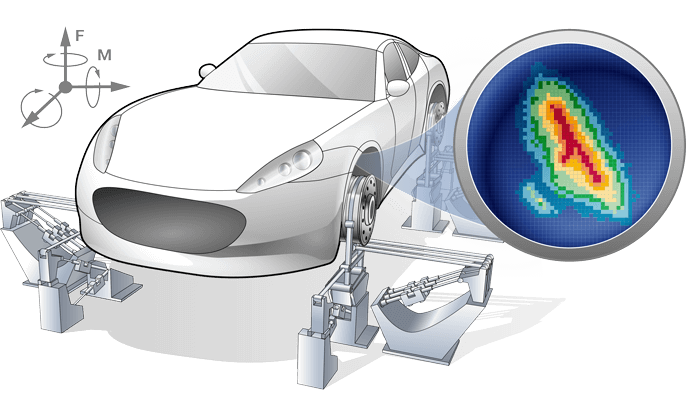

Functional Testing

Verifying proper operation of electronic systems.

Why QUALVIZ

QualViz provides a highly intuitive, user-friendly software environment, making it accessible to users without any programming expertise. The platform comes preloaded with all essential modules for industrial visual inspection. It offers seamless compatibility with a wide range of hardware brands, supports both Windows® and Linux® operating systems, and runs efficiently on embedded devices.

QualViz accelerates deployment with predefined output rules, enabling quick and efficient integration into your systems. Additionally, we collaborate with a global network of trusted partners to assist you in selecting the right hardware tailored to your business needs. Our team ensures smooth integration into your existing company-wide infrastructure.

We prioritize understanding your specific requirements to deliver tailored solutions that meet your unique needs. Our comprehensive support includes a free feasibility study, a 30-day free trial, expert guidance during and after deployment, and hands-on training to help your team maximize the potential of QualViz.